Separation of Mixtures

- Definition of Mixtures

- Types of Mixtures

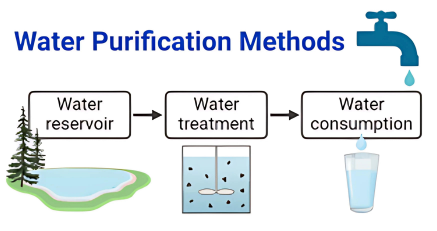

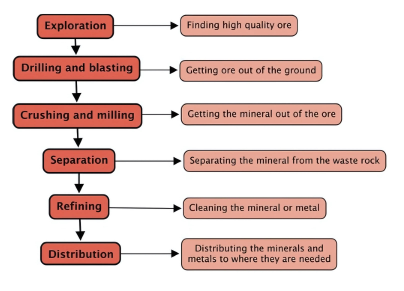

- Reasons for Separating Mixtures

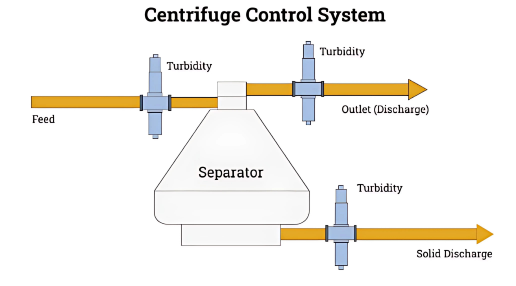

- Methods of Separating Mixtures

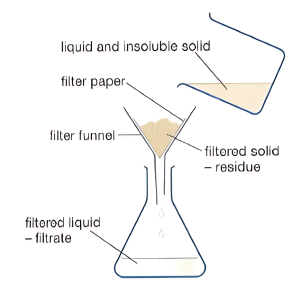

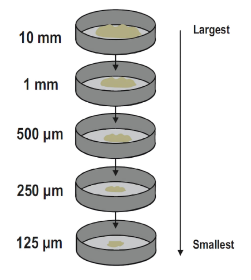

- Filtration

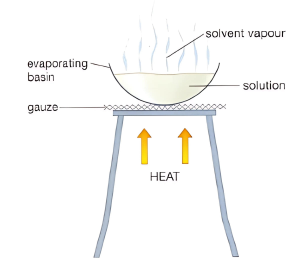

- Evaporation

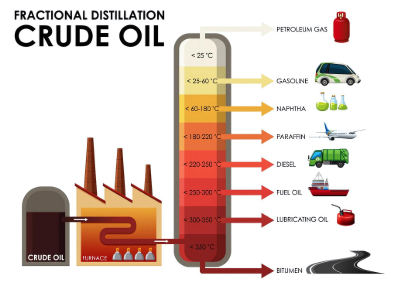

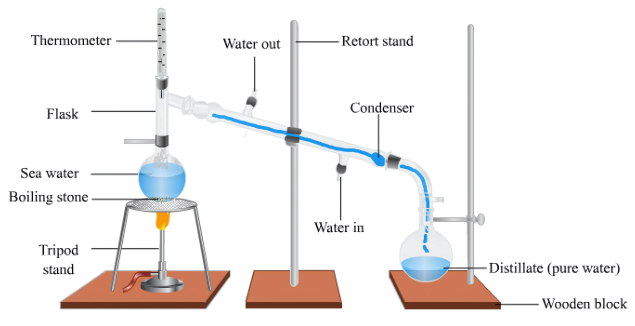

- Distillation

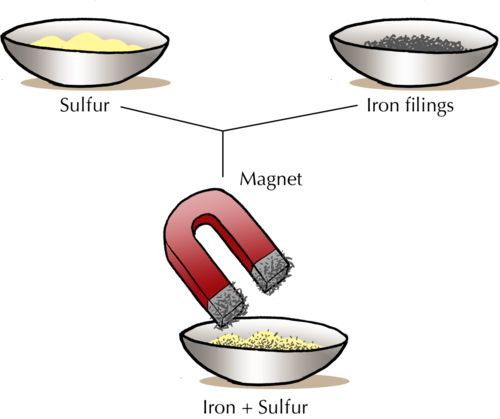

- Magnetic Separation

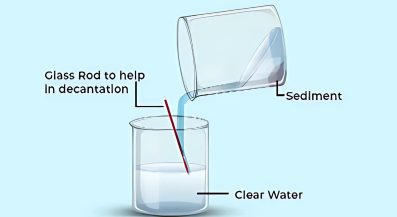

- Decantation

- Magnetic Separation of iron from sand

- Chromatography to separate the colors in ink

- Importance of Separation Techniques